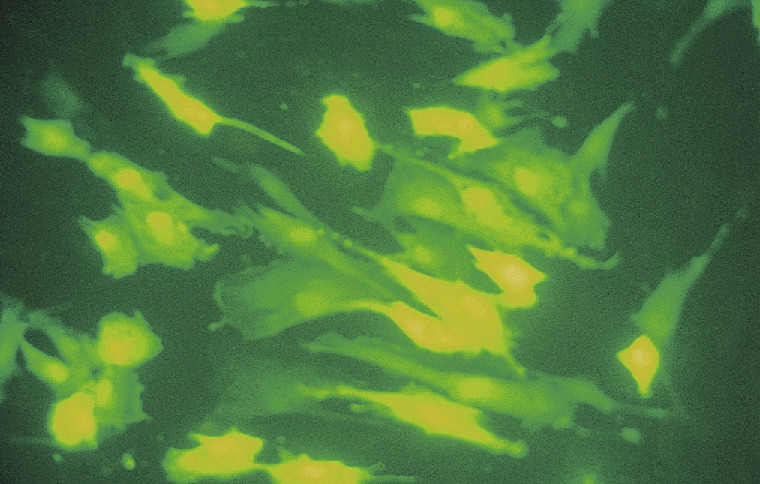

New developments in instrumentation, software, probes, and applications have resulted in a heightened popularity for a technique that was first observed over 150 years ago. There are many natural and synthetic compounds that exhibit fluorescence, and they have a number of different diagnostic, medical or biochemical applications.

For example, a fluorescent chemical substance or fluorophore can be attached to large biological molecule that is of interest and fluorescence can then be used to identify if the molecule of interest is present. This enables very specific analyses and, more importantly, quantitative results as the signal strength will depend on the number of fluorophores in the sample. Applications include DNA-sequencing, biochips, tumor and immunological marker detection.

Fluorescence is also used in many industrial applications, for example, to identify substances, surface coatings and final products. Applications include proof of authenticity (currency notes, expensive consumer products), inspection of coatings and tagging of fuel or oil. In addition, organic material when excited with UV-Light, will often display a strong auto-fluorescence and this attribute has a wide variety of applications without the need to use additional fluorescence markers. One such example would be the measurement of contamination (e.g. oil in water) and the detection of oil and fat residues on surfaces in hygiene testing.